(1) Strong corrosion resistance:

Usually made of 304 or 316 stainless steel, this flexible swivel features excellent corrosion resistance and can withstand corrosive environments, including seawater, acid, and alkali, far exceeding the service life of ordinary material swivel rings. Compared with ordinary swivels, a marine swivel made from stainless steel delivers a much longer service life, making it ideal for marine engineering, offshore equipment, ships, and chemical industry applications.

(2) Higher flexibility:

Compared with standard swivel devices, a stainless steel swivel provides greater flexibility and adaptability. This marine swivel can operate smoothly at multiple angles and directions, allowing bending and torsion while effectively reducing stress concentration on connecting parts, thus improving reliability and durability.

(3) Smooth rotation:

Internally equipped with high-precision bearings, the stainless steel swivel can achieve 360 ° unobstructed rotation, effectively preventing entanglement and twisting of connected ropes, chains, etc., ensuring the normal operation and safe operation of the equipment.

(4) Low maintenance cost:

Thanks to its corrosion-resistant stainless steel swivel design, it does not rust easily and requires minimal maintenance. This significantly reduces replacement frequency, operational costs, and downtime. Therefore, the marine swivel is especially suitable for long-term continuous operation equipment and critical working environments.

Hooks

Hooks Shackles

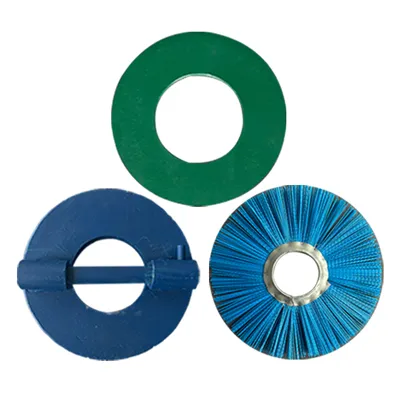

Shackles Rope Thimbles

Rope Thimbles Links & Rings

Links & Rings Kelly's Eye

Kelly's Eye Stoppers

Stoppers G Hooks & Recessed Links

G Hooks & Recessed Links Connectors

Connectors Tools

Tools Rockhopper Spare Parts

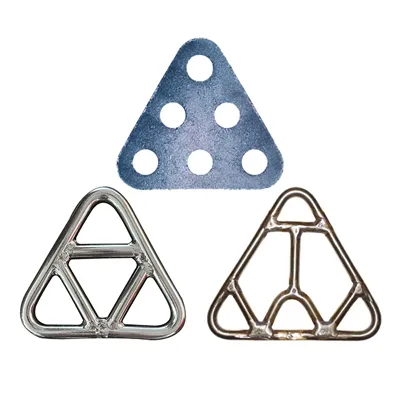

Rockhopper Spare Parts Triangles

Triangles Butterflies

Butterflies Chains

Chains Twine and Ropes

Twine and Ropes Wire Ropes

Wire Ropes Anchor Equipment

Anchor Equipment Wire Rope Clips

Wire Rope Clips Ferrules

Ferrules Terminals

Terminals Turnbuckles

Turnbuckles Fenders & Buoys

Fenders & Buoys Floats

Floats Lashing & Slings & Load Binders

Lashing & Slings & Load Binders Pulleys & Blocks

Pulleys & Blocks Wire / Chain Toggles

Wire / Chain Toggles

G100 Products

G100 Products Turnbuckles

Turnbuckles Shackles

Shackles Eye Bolts & Nuts

Eye Bolts & Nuts Forged Hooks

Forged Hooks Swivels

Swivels Wire Rope Clips & Grips

Wire Rope Clips & Grips Wire Rope Thimbles

Wire Rope Thimbles Snap Hooks

Snap Hooks Rings & Connector

Rings & Connector Lever Hoist

Lever Hoist Chain Binders

Chain Binders Wire Rope

Wire Rope Lifting Sling

Lifting Sling Ratchet Straps

Ratchet Straps Forestry Logging Supplies

Forestry Logging Supplies Pins

Pins Eye Plate

Eye Plate Wire Rope Ferrules

Wire Rope Ferrules Chains & Acccessories

Chains & Acccessories Quick Links

Quick Links Pulley & Blocks

Pulley & Blocks

Stainless Shackles

Stainless Shackles Stainless Hooks

Stainless Hooks Stainless Eye Bolts & Nuts

Stainless Eye Bolts & Nuts Stainless Terminals

Stainless Terminals Stainless Swivels

Stainless Swivels Stainless Thimbles

Stainless Thimbles Stainless Rings

Stainless Rings Stainless Quick Link

Stainless Quick Link Stainless Chains

Stainless Chains Stainless Pulleys

Stainless Pulleys Drop Forged Stainless

Drop Forged Stainless Stainless U Bolts

Stainless U Bolts Eye Plate, Eye Straps, Angles

Eye Plate, Eye Straps, Angles Stainless Steel Hinge

Stainless Steel Hinge Shade Sail Hardware

Shade Sail Hardware

EN

EN