Clarify: What is your chain supposed to do?

The first step in choosing a chain is not to look at the material or price, but to clarify the usage scenario. Different application scenarios have vastly different requirements for the chain.

Common application scenario classification:

• Lifting and hoisting: requires high safety factor and high strength

• Transmission and conveying: requires wear resistance and fatigue resistance

• Ship Terminal: Requires resistance to seawater corrosion

•Construction site: requires weather resistance and impact resistance

•Food and medicine: require hygiene grade and easy to clean

Material selection: The more expensive, the better

The material of the chain directly determines its service life and safety. I have sorted out several common materials on the market for everyone:

Advantages and disadvantages of material types, applicable scenarios

Carbon steel is cheap in price, has high strength, is prone to rusting, is not resistant to corrosion in dry indoor environments, and can be used for a short period of time

Hot dip galvanizing has good anti rust performance and high cost-effectiveness. The coating is prone to rusting after wear and tear. It is commonly used in outdoor environments and construction sites

304 stainless steel is corrosion-resistant, aesthetically pleasing, relatively expensive, slightly lower in strength, food grade, and suitable for general corrosive environments

316 stainless steel is acid and alkali resistant, resistant to seawater, and has the highest price in chemical, marine, and highly corrosive environments

Intensity level: Understand numbers such as G80 and G100

Many people get headaches when they see G80 and G100, but it's actually quite simple:

G80: Safety factor 4:1, suitable for general lifting operations

G100: Safety factor 5:1, suitable for heavy loads and frequent operations

Level 70/80: This is the strength level, the higher the number, the higher the strength

Important reminder: The higher the safety factor, the better. Although G100 is safer, it is also more expensive and heavier. If your homework intensity is not high, G80 is completely sufficient, there is no need to spend extra money.

Standard certification: Differences between DIN, ISO, and GB

The standard systems of different countries determine the quality level of the chain:

DIN standard: German industrial standard, known for its rigor, mainstream in the European market

ISO standards: International standards, globally applicable

GB standard: Chinese national standard, in compliance with domestic requirements

Size specifications: Don't just look at the diameter

Chain specifications are not just about diameter, but also include:

• Pitch: The distance between chain links, which affects flexibility and strength

• Inner width: affects the matching degree with hooks and shackles

• Breaking force: the maximum tensile force that the chain can withstand

Surface treatment: not just for aesthetics

Surface treatment directly affects the corrosion resistance of the chain:

Hot dip galvanizing: Thick coating, good rust prevention effect, suitable for outdoor use

Galvanized coating: Smooth surface, but thin coating, suitable for indoor use

Nickel plating: Beautiful and corrosion-resistant, but expensive

Natural color: No treatment, lowest price, but prone to rusting

Special reminder: After welding, hot-dip galvanized chains need to undergo rust prevention treatment at the weld seam, otherwise it will become a weak point of corrosion.

Usage environment: These factors must be considered

When choosing a chain, it is important to consider the usage environment:

• Temperature: High temperature will reduce the strength of the chain, while low temperature will make it brittle

• Humidity: Wet environments accelerate corrosion

•Chemical medium: Special materials are required for acidic and alkaline environments

• Impact load: Frequent impacts require a higher safety factor

Maintenance and upkeep: the key to extending lifespan

Even the best chain needs maintenance:

• Regular inspection: check for wear, deformation, and rust

• Timely lubrication: reduce wear and prevent rust

• Proper storage: dry and ventilated, avoid heavy pressure

• Scrap standard: If the wear exceeds 10% or cracks appear, it must be scrapped

If you have any further questions, please feel free to contact us at sales@clgrindustrial.com and we will do my best to answer them.

Hooks

Hooks Shackles

Shackles Rope Thimbles

Rope Thimbles Links & Rings

Links & Rings Kelly's Eye

Kelly's Eye Stoppers

Stoppers G Hooks & Recessed Links

G Hooks & Recessed Links Connectors

Connectors Tools

Tools Rockhopper Spare Parts

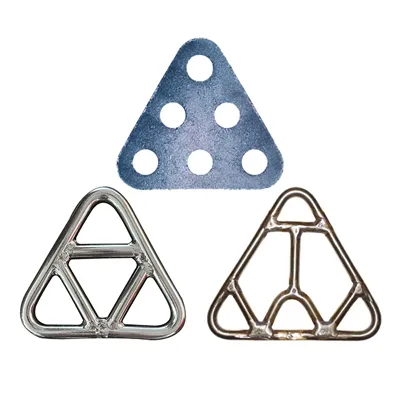

Rockhopper Spare Parts Triangles

Triangles Butterflies

Butterflies Chains

Chains Twine and Ropes

Twine and Ropes Wire Ropes

Wire Ropes Anchor Equipment

Anchor Equipment Wire Rope Clips

Wire Rope Clips Ferrules

Ferrules Terminals

Terminals Turnbuckles

Turnbuckles Fenders & Buoys

Fenders & Buoys Floats

Floats Lashing & Slings & Load Binders

Lashing & Slings & Load Binders Pulleys & Blocks

Pulleys & Blocks Wire / Chain Toggles

Wire / Chain Toggles

G100 Products

G100 Products Turnbuckles

Turnbuckles Shackles

Shackles Eye Bolts & Nuts

Eye Bolts & Nuts Forged Hooks

Forged Hooks Swivels

Swivels Wire Rope Clips & Grips

Wire Rope Clips & Grips Wire Rope Thimbles

Wire Rope Thimbles Snap Hooks

Snap Hooks Rings & Connector

Rings & Connector Lever Hoist

Lever Hoist Chain Binders

Chain Binders Wire Rope

Wire Rope Lifting Sling

Lifting Sling Ratchet Straps

Ratchet Straps Forestry Logging Supplies

Forestry Logging Supplies Pins

Pins Eye Plate

Eye Plate Wire Rope Ferrules

Wire Rope Ferrules Chains & Acccessories

Chains & Acccessories Quick Links

Quick Links Pulley & Blocks

Pulley & Blocks

Stainless Shackles

Stainless Shackles Stainless Hooks

Stainless Hooks Stainless Eye Bolts & Nuts

Stainless Eye Bolts & Nuts Stainless Terminals

Stainless Terminals Stainless Swivels

Stainless Swivels Stainless Thimbles

Stainless Thimbles Stainless Rings

Stainless Rings Stainless Quick Link

Stainless Quick Link Stainless Chains

Stainless Chains Stainless Pulleys

Stainless Pulleys Drop Forged Stainless

Drop Forged Stainless Stainless U Bolts

Stainless U Bolts Eye Plate, Eye Straps, Angles

Eye Plate, Eye Straps, Angles Stainless Steel Hinge

Stainless Steel Hinge Shade Sail Hardware

Shade Sail Hardware

EN

EN