What is Stainless Steel?

Stainless steel first appeared about a hundred years ago and has recently become widely used in building and construction. Today, it is one of the most popular metal alloys used in everyday life and production. Stainless steel has been easily incorporated into everyday life and has been the basis for the creation of many household appliances, decorative items and even utensils. This is due to its superior properties compared to other alloy analogues.

"Stainless steel" is a general term for a large group of alloy steels that contain at least 10.5% chromium in their composition. Above this chromium content, a complex chromium oxide surface layer, or protective film, is formed, which prevents more oxygen atoms from penetrating the steel and protects the iron in the matrix from rusting. This layer is what makes the steel "rust-free". Adding higher levels of chromium and other alloying elements (such as molybdenum and nickel) can enhance this protective barrier and further improve the corrosion resistance of stainless steel.

For rigging products, the most commonly used types are Type 304 and Type 316, also known as austenitic stainless steels. A large portion of the chemical composition of austenitic stainless steels (up to 33%) is associated with nickel and, of course, chromium. Consumers prefer these alloys because of their durability and their excellent resistance to rust.

What is The Difference Between Type 304 and Type 316 Stainless Steel?

In general, it is difficult to distinguish 304 and 316 stainless steel from each other by the naked eye from the surface. They both offer the same polished, chrome-plated, grained, colored or sandblasted appearance, but 316 stainless steel is more costly due to its enhanced chemical and production properties.

316 stainless steel has molybdenum added to its alloy composition during the manufacturing process. Molybdenum makes 316 more corrosion resistant than 304 stainless steel. This also makes 316 stainless steel more advantageous for withstanding extreme environmental conditions, such as salt water. For example, our customers in the fishing industry require stainless steel 316.

Because it is Stainless Steel, Doesn't That Mean it is Also Non-Magnetic?

This is not necessarily the case. In fact, 304 stainless steel usually has a detectable magnetic attraction, while 316 stainless steel may have a very slight magnetic attraction.

The reason for this is quite technical, but it has to do with the chromium content of the alloy and the manufacturing process of the part. 316 stainless steel has more chromium than 304 stainless steel, and it is the chromium that affects the microstructure of the steel surface. Because 316 stainless steel contains more nickel, and the presence of this additional nickel helps to enhance the influence of chromium in the steel, there is little detectable magnetic force in 316 stainless steel.

Typically, it is the cold working or welding of the metal that can produce magnetic forces. Cold working in the form of bending or machining can alter the microstructure of the metal surface and reduce the effect of the chromium layer on the surface. In addition, because 304 stainless steel has a lower nickel content than 316 stainless steel, it is more likely to produce some degree of magnetism.

How Can "Stainless Steel" Rust?

It is "stainless", not "impervious to contamination". Although stainless steel is more resistant to corrosion than ordinary carbon or alloy steel, corrosion can occur under certain conditions.

304 stainless steel is more prone to rusting than 316 stainless steel. This is due to the higher content of nickel and molybdenum. Stamping, bending and welding can damage the surface microstructure of stainless steel, especially for 304 stainless steel.

Salt water, airborne salts and chemicals will attack 304 stainless steel, causing pitting corrosion. the extra nickel and molybdenum in 316 stainless steel make it less likely to corrode when exposed to these same elements.

Electrochemical corrosion occurs when stainless steel comes in contact with different metals in the presence of water, electrolytes or other solutions.

Hooks

Hooks Shackles

Shackles Rope Thimbles

Rope Thimbles Links & Rings

Links & Rings Kelly's Eye

Kelly's Eye Stoppers

Stoppers G Hooks & Recessed Links

G Hooks & Recessed Links Connectors

Connectors Tools

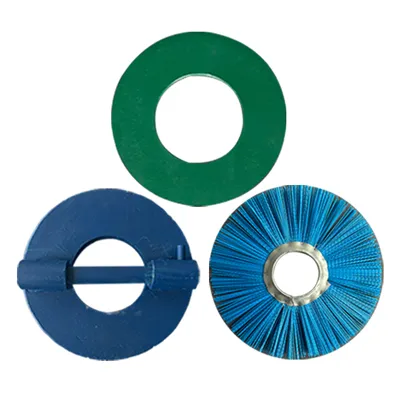

Tools Rockhopper Spare Parts

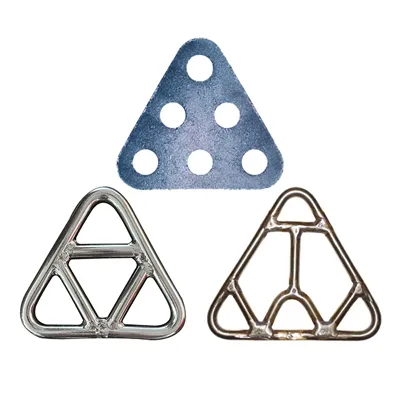

Rockhopper Spare Parts Triangles

Triangles Butterflies

Butterflies Chains

Chains Twine and Ropes

Twine and Ropes Wire Ropes

Wire Ropes Anchor Equipment

Anchor Equipment Wire Rope Clips

Wire Rope Clips Ferrules

Ferrules Terminals

Terminals Turnbuckles

Turnbuckles Fenders & Buoys

Fenders & Buoys Floats

Floats Lashing & Slings & Load Binders

Lashing & Slings & Load Binders Pulleys & Blocks

Pulleys & Blocks Wire / Chain Toggles

Wire / Chain Toggles

G100 Products

G100 Products Turnbuckles

Turnbuckles Shackles

Shackles Eye Bolts & Nuts

Eye Bolts & Nuts Forged Hooks

Forged Hooks Swivels

Swivels Wire Rope Clips & Grips

Wire Rope Clips & Grips Wire Rope Thimbles

Wire Rope Thimbles Snap Hooks

Snap Hooks Rings & Connector

Rings & Connector Lever Hoist

Lever Hoist Chain Binders

Chain Binders Wire Rope

Wire Rope Lifting Sling

Lifting Sling Ratchet Straps

Ratchet Straps Forestry Logging Supplies

Forestry Logging Supplies Pins

Pins Eye Plate

Eye Plate Wire Rope Ferrules

Wire Rope Ferrules Chains & Acccessories

Chains & Acccessories Quick Links

Quick Links Pulley & Blocks

Pulley & Blocks

Stainless Shackles

Stainless Shackles Stainless Hooks

Stainless Hooks Stainless Eye Bolts & Nuts

Stainless Eye Bolts & Nuts Stainless Terminals

Stainless Terminals Stainless Swivels

Stainless Swivels Stainless Thimbles

Stainless Thimbles Stainless Rings

Stainless Rings Stainless Quick Link

Stainless Quick Link Stainless Chains

Stainless Chains Stainless Pulleys

Stainless Pulleys Drop Forged Stainless

Drop Forged Stainless Stainless U Bolts

Stainless U Bolts Eye Plate, Eye Straps, Angles

Eye Plate, Eye Straps, Angles Stainless Steel Hinge

Stainless Steel Hinge Shade Sail Hardware

Shade Sail Hardware

EN

EN