Flat shuttle is the core tool for weaving and repairing fishing nets, with a bullet shaped or shuttle shaped appearance and a built-in shuttle core for winding the net wire. According to the usage scenario, flat shuttles are divided into three types: large, medium, and small. The large shuttle is 20-50 centimeters long and is mainly used for sealing fishing nets and repairing thick wire nets; Medium shuttle length 10-20 centimeters, suitable for weaving various fishing nets; Small shuttles are generally less than 10 centimeters and are mainly used for repairing fishing nets. The medium-sized shuttle we commonly use is very convenient to use because it combines the functions of both sizes and has a suitable length.

Material selection for flat shuttle

Modern flat shuttles are mainly made of the following materials:

Bamboo shuttle: Traditional material, lightweight and durable, but it is prone to producing sawdust after long-term use and requires regular polishing and maintenance.

Plastic shuttle: Made of ABS engineering plastic, lightweight, rust resistant, and affordable, it is currently the most commonly used material. Plastic shuttles have excellent wear resistance and impact resistance, with a service life of over six months, which is 4-5 times longer than that of wooden shuttles.

Metal shuttle: made of stainless steel or copper, with high strength but heavy weight, and relatively high price, suitable for professional mesh weaving.

From the perspective of cost-effectiveness and ease of use, plastic flat shuttles are the best choice. They not only maintain the tactile feel of traditional shuttles, but also solve the problems of wood shuttles being prone to wear and metal shuttles being bulky.

Preparation work for flat shuttle

1. Winding method

Winding is the first step in using a flat shuttle, and correct winding can greatly improve weaving efficiency. The specific steps are as follows:

Tie one end of the silk thread to the shuttle and wrap it in circles

Do not wrap too much to avoid affecting the weaving speed

It is recommended to prepare multiple shuttles with pre wound threads before each weaving to avoid frequent interruptions in the winding process

2. Choose a ruler board

The ruler board is a key tool for controlling the mesh size, usually 5-10 centimeters long, made of bamboo or aluminum plate. When choosing a ruler, it is important to note:

There is no strict requirement for the thickness of the ruler board, but both sides must be parallel

If the two sides of the ruler are not parallel, the woven mesh will be of different sizes

The upper and lower sides of the ruler should be kept parallel, with the upper side being thinner (about 1.5 millimeters) and the lower side being thicker (about 2-3 millimeters)

Fishing net repair techniques

1. Daily maintenance

After using the fishing net, it should be cleaned in a timely manner:

Rinse off dirt on the internet with clean groundwater or tap water

Hang in a cool and ventilated environment to fully dry

Do not expose to direct sunlight, as it will greatly reduce the lifespan of the fishing net

2. Damage repair

Minor damage repair:

For broken wires in a single mesh, use a shuttle directly to repair them

Using double knots, repeatedly connect and patch the left and right mesh holes

Ensure that the warranty repair is firm and avoids loose joints

Major damage repair:

Use scissors to cut the damaged part along the edge into a regular triangle or trapezoid

Use a ruler to start weaving from the top, using the same weaving method as weaving a fishing net

The joint part should be fastened tightly, and the joint should be glued firmly with 502 glue

After the repair is completed, it needs to be repainted with clear varnish

Precautions for use

1. Regular inspection: Check the shuttle for cracks or burrs before use, and polish it smooth in a timely manner

2. Proper storage: Used shuttles should be placed in a dry place to avoid moisture and deformation

3. Avoid overloading: Do not use a shuttle to pull heavy network cables to prevent the shuttle from breaking

4. Timely replacement: When the shuttle shows obvious wear or deformation, it should be replaced in a timely manner

5. Keep clean: Regularly clean the dirt and thread ends on the shuttle to ensure smooth use

Hooks

Hooks Shackles

Shackles Rope Thimbles

Rope Thimbles Links & Rings

Links & Rings Kelly's Eye

Kelly's Eye Stoppers

Stoppers G Hooks & Recessed Links

G Hooks & Recessed Links Connectors

Connectors Tools

Tools Rockhopper Spare Parts

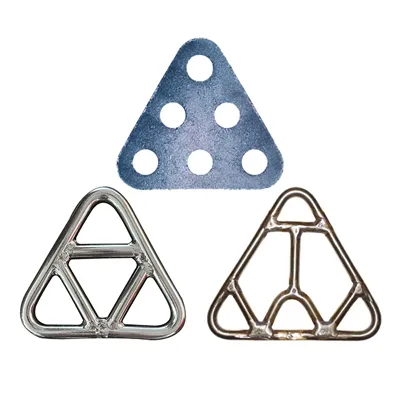

Rockhopper Spare Parts Triangles

Triangles Butterflies

Butterflies Chains

Chains Twine and Ropes

Twine and Ropes Wire Ropes

Wire Ropes Anchor Equipment

Anchor Equipment Wire Rope Clips

Wire Rope Clips Ferrules

Ferrules Terminals

Terminals Turnbuckles

Turnbuckles Fenders & Buoys

Fenders & Buoys Floats

Floats Lashing & Slings & Load Binders

Lashing & Slings & Load Binders Pulleys & Blocks

Pulleys & Blocks Wire / Chain Toggles

Wire / Chain Toggles

G100 Products

G100 Products Turnbuckles

Turnbuckles Shackles

Shackles Eye Bolts & Nuts

Eye Bolts & Nuts Forged Hooks

Forged Hooks Swivels

Swivels Wire Rope Clips & Grips

Wire Rope Clips & Grips Wire Rope Thimbles

Wire Rope Thimbles Snap Hooks

Snap Hooks Rings & Connector

Rings & Connector Lever Hoist

Lever Hoist Chain Binders

Chain Binders Wire Rope

Wire Rope Lifting Sling

Lifting Sling Ratchet Straps

Ratchet Straps Forestry Logging Supplies

Forestry Logging Supplies Pins

Pins Eye Plate

Eye Plate Wire Rope Ferrules

Wire Rope Ferrules Chains & Acccessories

Chains & Acccessories Quick Links

Quick Links Pulley & Blocks

Pulley & Blocks

Stainless Shackles

Stainless Shackles Stainless Hooks

Stainless Hooks Stainless Eye Bolts & Nuts

Stainless Eye Bolts & Nuts Stainless Terminals

Stainless Terminals Stainless Swivels

Stainless Swivels Stainless Thimbles

Stainless Thimbles Stainless Rings

Stainless Rings Stainless Quick Link

Stainless Quick Link Stainless Chains

Stainless Chains Stainless Pulleys

Stainless Pulleys Drop Forged Stainless

Drop Forged Stainless Stainless U Bolts

Stainless U Bolts Eye Plate, Eye Straps, Angles

Eye Plate, Eye Straps, Angles Stainless Steel Hinge

Stainless Steel Hinge Shade Sail Hardware

Shade Sail Hardware

EN

EN