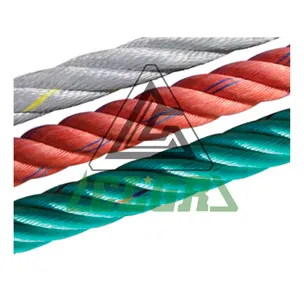

CLGR® Double Braided ropes cover four different materials: PP (polypropylene), nylon, polyester, and UHMWPE, accurately matching diverse work scenarios:

CLGR® PP (polypropylene) Double Braided Rope

Double Braided process enhances structural stability, and PP material combines lightweight and seawater corrosion resistance characteristics. Suitable for fishing trawl nets, outdoor lightweight towing and other scenarios, lightweight and easy to operate, long-term exposure to seawater is not easy to age, ensuring operational efficiency and rope life.

CLGR® Nylon Double Braided Rope

The double weave structure is resistant to twisting and wear, and the nylon material endows it with high toughness and tensile strength. Suitable for lifting operations, ship mooring, and other scenarios, it can withstand heavy loads without easily breaking, maintain stable performance even after repeated use, and improve operational safety and reliability.

CLGR® Polyester Double Braided Rope

The double Braided process ensures a compact structure, and the polyester material has excellent creep resistance and weather resistance. Suitable for industrial traction, heavy load fixation and other scenarios, it is not easily deformed under long-term stress, resistant to ultraviolet radiation and aging in outdoor environments, and stably supports heavy load operations.

CLGR® UHMWPE Double Braided Rope

The dual structure overlay UHMWPE has ultra-high strength and low elongation characteristics, suitable for extreme scenarios such as polar scientific research and ocean engineering. It can withstand super strong tensile force while maintaining low deformation, with excellent cutting resistance and wear resistance, providing reliable guarantee for extreme operations.

Hooks

Hooks Shackles

Shackles Rope Thimbles

Rope Thimbles Links & Rings

Links & Rings Kelly's Eye

Kelly's Eye Stoppers

Stoppers G Hooks & Recessed Links

G Hooks & Recessed Links Connectors

Connectors Tools

Tools Rockhopper Spare Parts

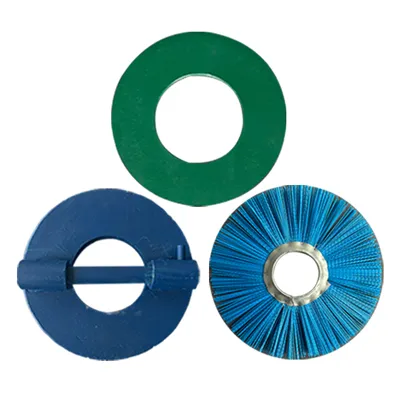

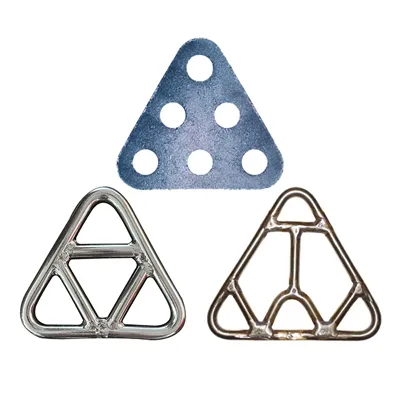

Rockhopper Spare Parts Triangles

Triangles Butterflies

Butterflies Chains

Chains Twine and Ropes

Twine and Ropes Wire Ropes

Wire Ropes Anchor Equipment

Anchor Equipment Wire Rope Clips

Wire Rope Clips Ferrules

Ferrules Terminals

Terminals Turnbuckles

Turnbuckles Fenders & Buoys

Fenders & Buoys Floats

Floats Lashing & Slings & Load Binders

Lashing & Slings & Load Binders Pulleys & Blocks

Pulleys & Blocks Wire / Chain Toggles

Wire / Chain Toggles

G100 Products

G100 Products Turnbuckles

Turnbuckles Shackles

Shackles Eye Bolts & Nuts

Eye Bolts & Nuts Forged Hooks

Forged Hooks Swivels

Swivels Wire Rope Clips & Grips

Wire Rope Clips & Grips Wire Rope Thimbles

Wire Rope Thimbles Snap Hooks

Snap Hooks Rings & Connector

Rings & Connector Lever Hoist

Lever Hoist Chain Binders

Chain Binders Wire Rope

Wire Rope Lifting Sling

Lifting Sling Ratchet Straps

Ratchet Straps Forestry Logging Supplies

Forestry Logging Supplies Pins

Pins Eye Plate

Eye Plate Wire Rope Ferrules

Wire Rope Ferrules Chains & Acccessories

Chains & Acccessories Quick Links

Quick Links Pulley & Blocks

Pulley & Blocks

Stainless Shackles

Stainless Shackles Stainless Hooks

Stainless Hooks Stainless Eye Bolts & Nuts

Stainless Eye Bolts & Nuts Stainless Terminals

Stainless Terminals Stainless Swivels

Stainless Swivels Stainless Thimbles

Stainless Thimbles Stainless Rings

Stainless Rings Stainless Quick Link

Stainless Quick Link Stainless Chains

Stainless Chains Stainless Pulleys

Stainless Pulleys Drop Forged Stainless

Drop Forged Stainless Stainless U Bolts

Stainless U Bolts Eye Plate, Eye Straps, Angles

Eye Plate, Eye Straps, Angles Stainless Steel Hinge

Stainless Steel Hinge Shade Sail Hardware

Shade Sail Hardware

EN

EN