-

Fishing & Trawling

Swivels

Hooks

Hooks Shackles

Shackles Rope Thimbles

Rope Thimbles Links & Rings

Links & Rings Kelly's Eye

Kelly's Eye Stoppers

Stoppers G Hooks & Recessed Links

G Hooks & Recessed Links Connectors

Connectors Tools

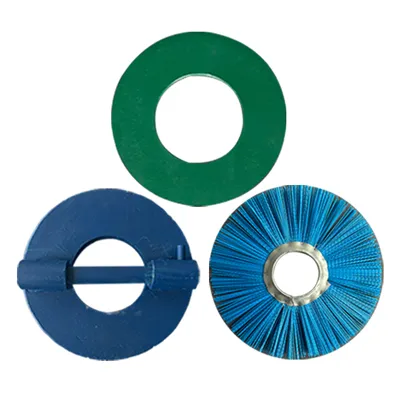

Tools Rockhopper Spare Parts

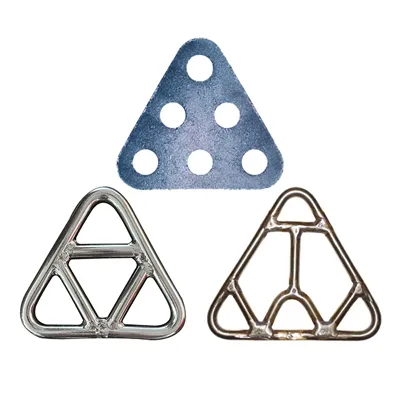

Rockhopper Spare Parts Triangles

Triangles Butterflies

Butterflies Chains

Chains Twine and Ropes

Twine and Ropes Wire Ropes

Wire Ropes Anchor Equipment

Anchor Equipment Wire Rope Clips

Wire Rope Clips Ferrules

Ferrules Terminals

Terminals Turnbuckles

Turnbuckles Fenders & Buoys

Fenders & Buoys Floats

Floats Lashing & Slings & Load Binders

Lashing & Slings & Load Binders Pulleys & Blocks

Pulleys & Blocks Wire / Chain Toggles

Wire / Chain Toggles

-

Lifting & Rigging

G80 Products

G100 Products

G100 Products Turnbuckles

Turnbuckles Shackles

Shackles Eye Bolts & Nuts

Eye Bolts & Nuts Forged Hooks

Forged Hooks Swivels

Swivels Wire Rope Clips & Grips

Wire Rope Clips & Grips Wire Rope Thimbles

Wire Rope Thimbles Snap Hooks

Snap Hooks Rings & Connector

Rings & Connector Lever Hoist

Lever Hoist Chain Binders

Chain Binders Wire Rope

Wire Rope Lifting Sling

Lifting Sling Ratchet Straps

Ratchet Straps Forestry Logging Supplies

Forestry Logging Supplies Pins

Pins Eye Plate

Eye Plate Wire Rope Ferrules

Wire Rope Ferrules Chains & Acccessories

Chains & Acccessories Quick Links

Quick Links Pulley & Blocks

Pulley & Blocks

-

Stainless Products

Stainless Turnbuckles

Stainless Shackles

Stainless Shackles Stainless Hooks

Stainless Hooks Stainless Eye Bolts & Nuts

Stainless Eye Bolts & Nuts Stainless Terminals

Stainless Terminals Stainless Swivels

Stainless Swivels Stainless Thimbles

Stainless Thimbles Stainless Rings

Stainless Rings Stainless Quick Link

Stainless Quick Link Stainless Chains

Stainless Chains Stainless Pulleys

Stainless Pulleys Drop Forged Stainless

Drop Forged Stainless Stainless U Bolts

Stainless U Bolts Eye Plate, Eye Straps, Angles

Eye Plate, Eye Straps, Angles Stainless Steel Hinge

Stainless Steel Hinge Shade Sail Hardware

Shade Sail Hardware

- Deck Hardware

- Company

- Resources

EN

EN